StormSafe Cartridge Vault

Fabco’s StormSafe Cartridge Vault is ideal for central drainage areas that require

stormwater treatment beyond the simple gross pollutants and trash removal.

Learn more about our unique design.

StormSafe Filter Cartridge Vault System Overview

The StormSafe Filter Cartridge Vault System are ideal for central drainage areas that require stormwater treatment beyond simple gross pollutants and trash removal. By utilizing the same proven filter technology from the StormBasin product line, the StormSafe Cartridge Vault can reduce concentrations of targeted stormwater pollutants in a cost-effective manner. The StormSafe Cartridge Vault is ideal for parking areas, storage areas and maintenance yards that have high concentrations of heavy metals, and oils & grease loads. The StormSafe Cartridge Vault is a good choice for projects with a treatment flow rate of 3 cubic feet/sec or less.

Relative to competitor vault systems, the StormSafe Cartridge Vault is designed to provide a highly effective treatment solution within a small foot print.

Multi-Chamber Filter Cartridge Vault System

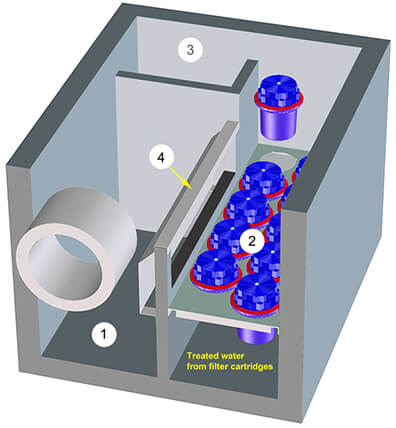

Inside the StormSafe Cartridge Vault there are 3 discrete chambers:

- Chamber 1: Pretreatment Chamber – Untreated water enters the StormSafe here

- Chamber 2: Filtration Chamber – Contains the filter cartridges.

- Chamber 3: Outlet Chamber – Located behind the Pretreatment and Filtration chambers, the Outlet chamber contains the outfall pipe

StormSafe Cartridge Vault Model

StormSafe Filter Cartridge Vault System Treatment Process

Stormwater runoff enters the vault through the Pretreatment chamber where the heaviest sediments begin to separate from the water and drop to the bottom of the chamber. As the runoff fills the chamber the water level rises upwards towards a rectangular opening or weir passing through the wall to the Filtration Chamber.

To protect the Filtration Chamber from the floating trash, debris, and oils/grease in the runoff, the opening/weir connecting the Pretreatment to the Filtration Chamber is equipped with a full length hood (See location 4 in the drawing). This submerged hood, acts like an oil/water separator trapping floating material in the Pretreatment Chamber. This simple process protects the filter cartridges – extending their service life and allowing optimum treatment flow rates.

Water leaving the Pretreatment Chamber enters the Filtration Chamber where it is filtered through Fabco cartridges held in a permanently installed mounting plate. The treated water leaving the cartridges drops down below the mounting plate and flows directly into the Outlet Chamber where it exits the treatment process.

Internal Emergency Bypass

If the inlet hood between the Pretreatment Chamber and the Filtration Chamber becomes blocked or if the total flow rate to the StormSafe exceeds the system treatment capacity, water can bypass the internal dividing walls and into the Outlet Chamber thereby providing additional hydraulic capacity.

Specifying and Designing Fabco’s StormSafe Stormwater Filter System

The StormSafe is a sub-surface Fabco stormwater vault system that utilizes Facbo’s proprietary filter media cartridges.

The external structure for the StormSafe is a concrete precast product that can have a round or rectangular shape depending on many things, including: treatment flow rate, required bypass flow rate, or pipe materials and elevations to name just a few of the parameters that affect the overall form and function of the filter.

Fabco typically works between the customer and a commercial concrete company located near the construction site to design and supply the vault. This allows us to optimize the design for the application while at the same time managing the costs, required modifications (if any), production time frame and delivery of the vault.

To being the design process, Fabco’s engineering group requires detailed information related to the construction site where the StormSafe will be installed and the functional stormwater treatment expected from the filter.

At a minimum, the following is required:

- Final Rim Elevation

- Invert Elevation Pipes (A 24″ offset between IN/OUT inverts is preferred for StormSafe units)

- Pipe Size and Material (HDPE, RCP, PVC, etc.)

- Orientation of Pipes into the Vault (Plan View)

- Sump Depth of the Unit (If Required)

- Targeted Pollutants

- Treatment Flow Rate (Please include any required Storm Event Specifications from the Design Engineer)

- On-line or Off-line Bypass Required

- Site Location and Site Plan

- Expected Lead Time

- Any Competitor Unit Spec’d on plans.

StormSafe Cartridge Filter Box

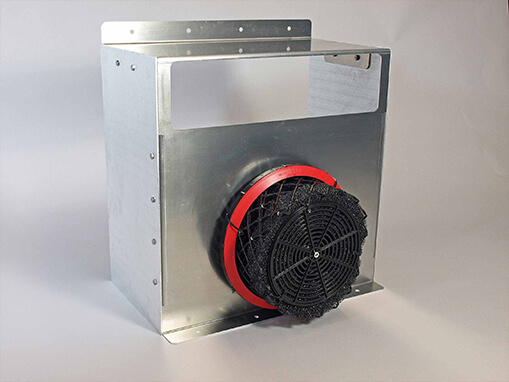

Cartridge Filter Box

The StormSafe Cartridge Filter Box is a smallest version of the StormSafe family and is normally specified with between 1 and 4 filter cartridges. This design can be used in most small vaults sizes and forms. The simplest designs consists of an aluminum box which accepts the cartridges and also include an open bypass port. In some cases a tall aluminum support frame is provided depending on the vault being used to lift the Cartridge Filter Box vertically, shown in the picture to the left.

Cartridge Filter Box with Installed Filter

Cartridge Filter Box without Filter Cartridge

Fabco Filter Cartridge

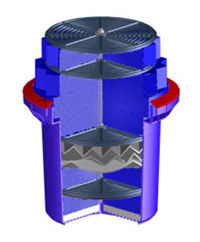

Our filter cartridges are designed to provide effective treatment of stormwater while maintaining high flow rates throughout the life of the cartridge. Filter cartridges are available in various configurations allowing you to fine tune performance in terms of sediments and debris, heavy metals, hydrocarbons/toxic chemicals, pathogens/bacteria and nutrients. The lightweight filter cartridge comes fully assembled and snaps securely in place with a quick twist. The modular cartridge design allows quick and easy replacement while containing the spent material for safe transport and disposal.

Our filter cartridges are designed to provide effective treatment of stormwater while maintaining high flow rates throughout the life of the cartridge. Filter cartridges are available in various configurations allowing you to fine tune performance in terms of sediments and debris, heavy metals, hydrocarbons/toxic chemicals, pathogens/bacteria and nutrients. The lightweight filter cartridge comes fully assembled and snaps securely in place with a quick twist. The modular cartridge design allows quick and easy replacement while containing the spent material for safe transport and disposal.

2-Stage Filtration

Each Fabco filter cartridge is composed of a standard pre-filter section, and a main filter chamber which can be configured to target specific pollutants.

Pre-Filter

The pre-filter is manufactured using FABGUARD antimicrobial treated open cell Polymer foam pads. The coarse open cell foam acts as a mechanical pre-filter for the cartridge restricting coarse sediments, trash and debris while allowing mostly water to flow through. Stormwater passing through the complex cellular structure contacts the antimicrobial treated internal walls substantially reducing the growth and passage of pathogens through the cartridge.

Proprietary Treatment Technologies

Fabco offers 5 filtration configurations (Standard, HV metals, Pathogens/bacteria, HV Hydrocarbons, Nutrients) using a combination of the following treatment technologies:

- FABMAX: This chemical treatment is applied to our open cell polymer foam filtering media. It is hydrophobic and instantly bonds to any hydrocarbons in the water matrix.

- FABSORB: This oil absorbent fabric material is used for treating free and emulsified oils, greases and other hydrocarbon-based compounds. This non-woven, filter can absorb 10 to 20 times its own weight in oil, greases and hydrocarbons.

- FABLITE: This natural mineral compound removes heavy metals as well as low levels of dissolved pollutants like hydrocarbons and other toxic chemicals.

- FABPHOS: This proprietary filtering media treats soluble, ortho-phosphates in stormwater runoff. FABPHOS also is effective in reducing nitrogen compounds thus assisting stormwater managers meet the >40% N reduction required by many states.

- FABGUARD: This antimicrobial shield is a patented chemical technology that when applied to our foam material makes it antimicrobially active. FABGUARD fuses with the material and will not wash out, or leach into the environment. Microorganisms that contact the material are neutralized.

Currently Fabco Industries offers a variety of filter cartridge types which can be used interchangeably in our StormSafe and StormBasin product lines.

Fabco Industries Vault Checklist Form

Fabco Industries is a leader in stormwater filtration treatment products and engineering. Solve virtually any stormwater pollution challenge with our sustainable, simple-to-maintain filtration solutions. Our stormwater products are highly effective for various applications including retrofits, new construction, and green infrastructure.